Maprom MK-Separator

Bearing Wear Preventer

The MK Separator continuously cleans abrasive particles laden water for optimal bearing & seals lubrication. Filter inserts are no longer required.

Optimum Solution

The MK Separator shows the highest grade of separation in combination with a low-pressure loss. Abrasive particles are removed effortlessly from the bearing lubricant flow. The operating principle is simple and based on centrifugal force. The unique shape of the inlet chamber brings the liquid in a fast rotational movement, resulting in a centrifugal force that directs the sand particles to the wall of the separator. The cleaned water is directed to the outlet. A small amount of water carries the abrasive particles overboard through the dirt discharge.

Easy installation and maintenance free

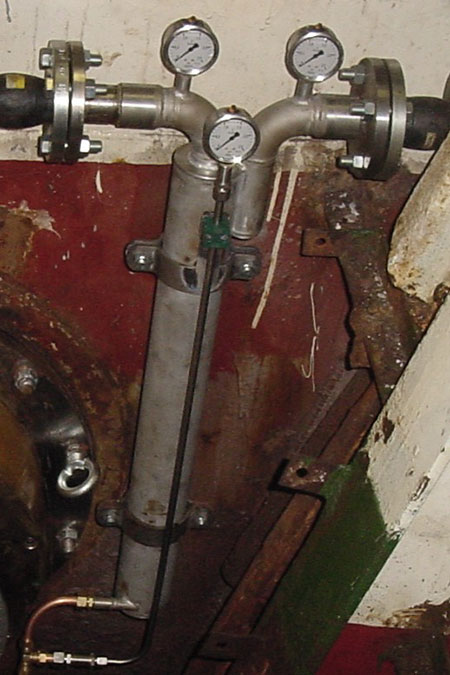

The seawater resistant MK Separator has no moving parts subjected to wear or elements that must be replaced periodically. Dirt is discharged automatically and continuously, thus no maintenance and no regular replacement of filter inserts is required. It can easily be installed even in an existing pipeline, because of its unique design with inlet- and outlet opposite and in one line. The separator can be fitted into existing pressure lines, on each desirable place between the pump and the stern tube. The operational process can be checked by the pressure gauge on in- and outlet and the discharge overboard. The separator can be installed in a simple way on new or existing vessels, providing a fine-grained “filter” and makes the risk of clogging and thus maintenance, redundant.

Apart from cleaning sand-laden bearing lubrication water, a built-in separator also prevents clogging in main engines/gearbox and other cooling/cleaning processes onboard.

Sizes range from 35 ltr/min up to 550 m3/hr and can be combined for larger flows.