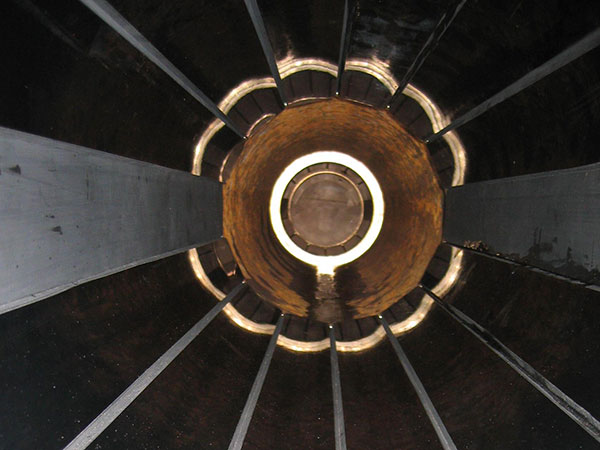

Maprom Water-Lubricated Bearings

Supporting your Power

Our water-lubricated bearings are recognized to be the best in the market, characterized by a low coëfficient of friction and their inherent vibration dampening.

Our water-lubricated bearings are recognized to be the best in the market, characterized by a low coëfficient of friction and their inherent vibration dampening.

Looking for more information on our products or the best solution to your challenge? Meet us and discover how we meet or exceed your requirements in accordance with - and ahead of - all applicable quality, safety and environmental standards.

Leave a message and we’ll get back to you or call us at +31 (0) 78 618 08 77.

Cage Code : H0U17

Owners of a wide array of different vessels choose the high quality solutions Maprom Engineering provides: