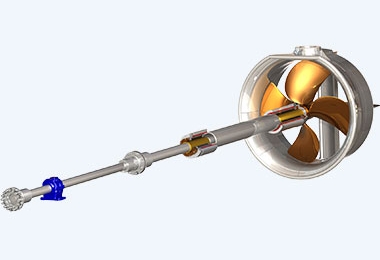

Maprom Propeller Shaft Systems

Driven by Perfection

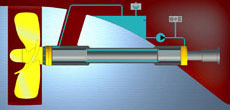

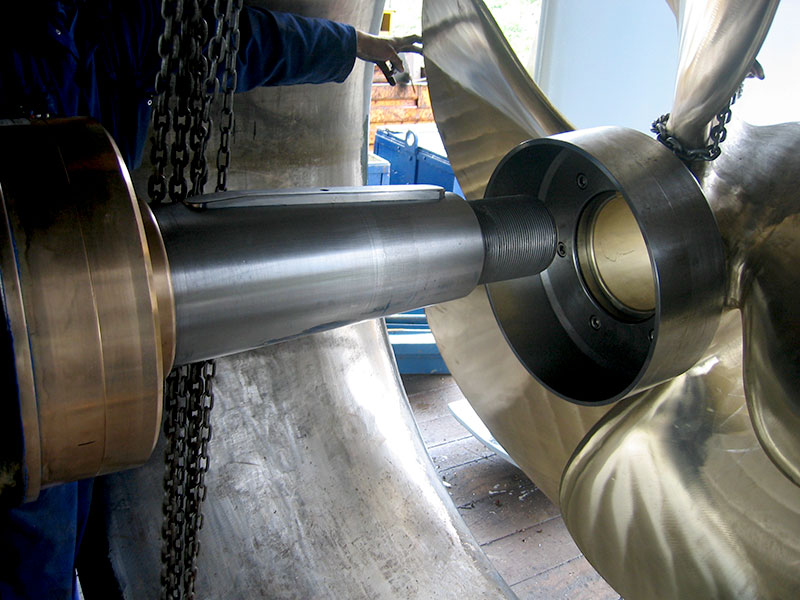

A Maprom water-lubricated propeller shaft system operates in either open- or closed- stern tube layout. Unlike others, Maprom systems function well with fresh water, seawater and/or brackish water. Additives against freezing may be used (subject to Maprom recommendation) but are not necessary and thus environmentally sound systems are guaranteed. Maprom water-lubricated stern tube systems are widely and successfully used in both inland and sea going vessels, ranging in shaft standard diameter from 85 up to 1050 mm and beyond.